In the intricate world of dentistry, precision is paramount. Dental professionals constantly seek out the most advanced tools to deliver the highest quality care to their patients. Among these essential instruments are dental carbide burs – the unsung heroes of the dental operatory. These small but mighty tools have revolutionized dental procedures, enabling dentists to work with unparalleled accuracy and efficiency.

Understanding Dental Carbide Burs

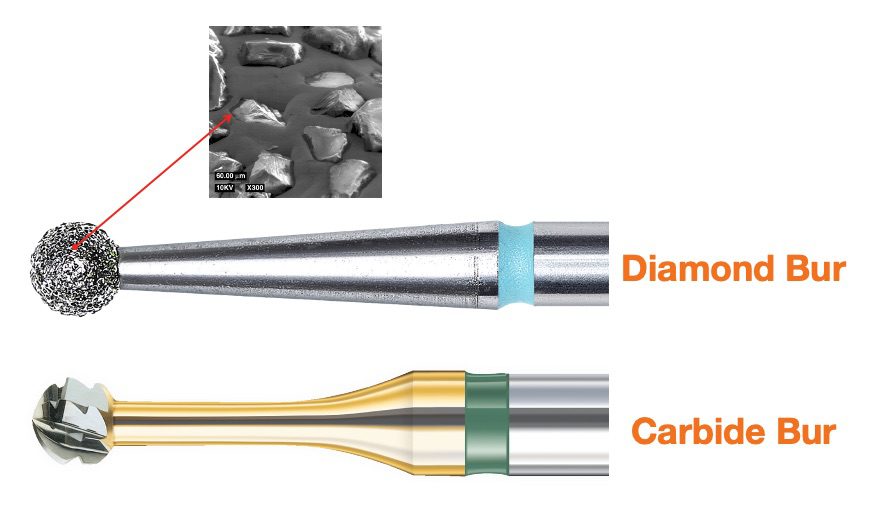

Dental carbide burs are rotary cutting instruments crafted from a robust combination of tungsten carbide and cobalt. This super-hard, extremely resistant material makes them ideal for a wide range of dental applications. Each bur is meticulously designed for specific tasks, with variations in shape, size, and grit to cater to different needs.

The anatomy of a dental bur consists of three main parts:

- The head: This is where the cutting action happens. The head features blades or grit, which can be made from various materials like gold or diamonds, each serving a specific purpose.

- The neck: This part connects the head to the shank and provides stability during use.

- The shank: This is the part that fits into the dental handpiece, allowing the bur to rotate at high speeds.

Dental carbide burs are classified according to the type of rotary instrument they are compatible with. For instance, burs for high-speed dental turbines (TURBINE or FG) are smaller in size, while those for low or medium-speed contra-angle handpieces (CONTRA ANGLE or RA) are of intermediate size.

Types of Dental Carbide Burs

There are hundreds of varieties of dental carbide burs, each designed for specific applications. Some of the most commonly used shapes include:

- Ball Mill: Perfect for caries removal, cavity openings in surgery, and creating orientation grooves in prosthetics.

- Cylindrical burs, right-angle head: Ideal for providing flat surfaces.

- Cylindrical burs, curved head: Suitable for creating occlusal orientation grooves.

- Cone drill, right-angle head: Perfect for making steps and defining the end line of prosthetic preparations.

- Inverted cone drill: Ideal for preparing retentive cavities.

Advantages of Dental Carbide Burs

Dental carbide burs offer a range of advantages that make them a preferred choice for many dental procedures:

Cutting Efficiency

Carbide burs are known for their swift cutting efficiency. They are particularly effective for cavity and filling procedures, where they cut through enamel, dentin, and composites with ease. This allows for efficient removal of elements that may interfere with the filling, including plaque.

Precision and Control

Carbide burs offer excellent precision and control. They are designed to cut rather than grind, creating smoother surface environments than their diamond counterparts. This precision ensures that the tooth’s inner pulp tissue is not damaged, making them ideal for meticulous removal of tooth structures.

Durability

Made from tungsten carbide, a material much harder than steel, carbide burs are highly durable and resistant to wear and tear. This robust construction allows them to withstand various dental procedures, significantly extending their lifecycle.

Heat Resistance

Carbide burs are more resistant to heat compared to other types of burs. This is crucial in maintaining cool temperatures during dental procedures, ensuring patient comfort and reducing the risk of thermal damage to the tooth.

Versatility

Carbide burs come in a wide range of shapes and sizes, catering to diverse dental procedures. Whether it’s preparing teeth for cavity fillings, removing fillings, or other dental procedures, there’s a carbide bur designed to meet the specific needs.

| Advantage | Description |

|---|---|

| Cutting Efficiency | Swiftly cuts through enamel, dentin, and composites, making them effective for cavity and filling procedures. |

| Precision and Control | Offers excellent precision and control, allowing for meticulous removal of tooth structures. |

| Durability | Made from tungsten carbide, a material much harder than steel, making them highly durable and able to withstand various dental procedures. |

| Heat Resistance | More resistant to heat compared to other types of burs, ensuring patient comfort during dental procedures. |

| Versatility | Available in a wide range of shapes and sizes, catering to diverse dental procedures. |

Top Carbide Burs in Dentistry

Two of the top carbide burs in the industry are the KaVo Kerr™ Regular Operative Carbide Burs and the Midwest® Once™ Sterile Operative Carbide Burs.

Midwest Once Sterile Operative Carbide Burs

Midwest Once Sterile Operative Carbide Burs are known for their sterile, single-use design. They are sterilized in individual pouches for easy use, guaranteeing a sharp bur each time, which reduces the risk of patient cross-contamination. These burs offer exceptional cutting performance and are available in an extensive selection of shapes and sizes to meet various clinical needs.

Moreover, Midwest Once Sterile Carbide Burs are designed with patient safety in mind. They are individually packaged and sterile, improving infection control. The single-use design eliminates the need for cleaning and autoclaving, saving time and money. Furthermore, they are always sharp, ensuring optimal cutting efficiency at all times.

KaVo Kerr Regular Operative Carbide Burs

KaVo Kerr Regular Operative Carbide Burs are renowned for their unique plating technology. They are designed to cut with excellence and ease, providing precise results every time. These burs are available in a wide variety of shapes and sizes, making them versatile for different dental procedures.

The pear shape of KaVo Kerr Regular Operative Carbide Burs is one thing that makes them stand out. This shape creates mechanical retention and keeps the full-length enamel rod margins on pit and fissure surfaces. This unique plating technology, combined with smaller head diameters, allows for faster cutting.

Both KaVo Kerr and Midwest Once Carbide Burs are top choices in the dental industry, each with their unique advantages. KaVo Kerr burs are known for their unique plating technology and versatile portfolio, offering sizes and shapes essential for achieving optimal aesthetic results. On the other hand, Midwest Once burs are recognized for their sterile, single-use design, which guarantees a sharp bur each time and reduces the risk of patient cross-contamination.

The choice between the two often depends on the specific needs of the dental procedure and the preferences of the dental professional. Regardless of the choice, both brands are committed to providing high-quality, reliable tools for dental professionals.

Maintenance and Sterilization of Dental Burs

Proper care and sterilization of dental burs are crucial for ensuring their effectiveness and longevity, as well as maintaining high standards of dental hygiene. Here are some general usage tips and recommended cleaning and sterilization procedures:

General Usage Tips

- Only qualified dentists should work with dental burs for the safety of both the user and the patient.

- Sterilize all burs before each use and replace them frequently to avoid using a dull, worn, or damaged bur on a patient.

- A dull or damaged bur could result in reduced efficiency and possible harm to the patient.

Cleaning and Maintenance

- Always wear gloves when handling contaminated instruments.

- Presoak the burs for at least 10 minutes in a disinfection solution designed for dental burs that contains a corrosion inhibitor to minimize the dulling of the diamond coating.

- Use a brush to clean the burs thoroughly if needed, then rinse several times to remove the disinfection solution.

- Dry the burs and store them in a clean and moisture-free environment.

Alternatively, burs may be ultrasonically cleaned by inserting them in bur holders. A cycle of 5 minutes is recommended, using a general-purpose cleaner. Rinse several times after cleaning, then dry the burs and store them in a clean and moisture-free environment.

Sterilization

- Place the burs in sterilization bags and autoclave them for at least 10 minutes at a temperature of 135°C.

- Dry the burs and store them in a clean and moisture-free environment.

Alternatively, use a dry heat sterilizer at 170°C (340°F) for 1 hour. When used according to the manufacturer’s instructions, this will not corrode or dull carbide burs. Avoid cold sterilizing solutions as they contain oxidizing agents which may weaken carbide burs.

Common Mistakes to Avoid

Several common mistakes can compromise the effectiveness of dental burs and potentially harm patients. These include:

- Using the wrong type of bur for a specific procedure or material

- Applying too much pressure or force when using a handpiece

- Failing to properly lubricate and maintain the handpiece

- Not properly sterilizing or cleaning the handpiece

- Overheating the bur or handpiece due to prolonged use

- Using a dull or worn-out bur

- Ignoring warning signs of potential problems with the handpiece

- Failing to properly secure the bur in the handpiece

- Not using adequate water or air cooling during the procedure

- Improper handling or storage of the handpiece

Conclusion

Dental carbide burs have indisputably transformed dentistry, enabling precise and efficient treatments. As dental technology continues to advance, these tools will likely see further enhancements, solidifying their role in the pursuit of dental excellence.

By understanding the types, advantages, and top choices of dental carbide burs, as well as following proper maintenance and sterilization procedures, dental professionals can harness the full potential of these powerful tools to deliver the highest quality care to their patients.

At VeepDental, we are committed to providing dental professionals with the best tools and equipment to enhance their practice. As a professional dental equipment manufacturer since 2010, we offer a wide range of high-quality products, including dental carbide burs, curing lights, chair control systems, LED lamps, endomotors, apex locators, and more.

Our team of experts meticulously controls every process, from raw material selection to software design and development, PCB processing to half-finished product inspection, and whole unit installation to delivery testing. This ensures that our products meet the highest standards of quality and performance.

For more information on our dental carbide burs and other products, please visit our website or contact our customer service team. We are here to help you enhance precision and deliver exceptional care to your patients.